Safety, Health, Environment

SHE Policy

As a 'Global ESG Material Solutions Company', SKC has adopted Safety/Health/Environment (SHE) as the agenda with the highest priority in its management activities.

Business Management System

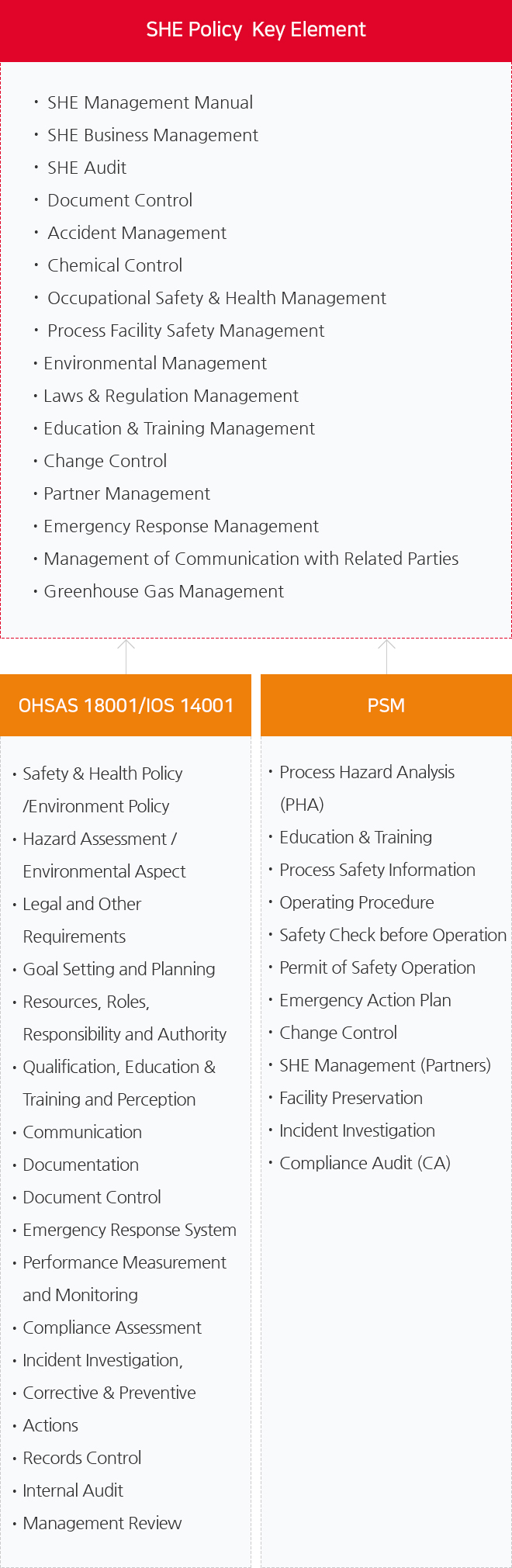

In 2015, SKC set a new SHE policy and improved the SHE management system to have the policy implemented across its business sites.

We are able to keep moving forward to accumulate technology according to the operating system in virtuous cycle based on 16 major components, build personal and organizational competences and spread the SHE culture.

We are able to keep moving forward to accumulate technology according to the operating system in virtuous cycle based on 16 major components, build personal and organizational competences and spread the SHE culture.

GREENHOUSE GAS MANAGEMENT

We at SKC have engaged in a variety of activities for the reduction of greenhouse gas (GHG) emissions since we were selected as a business managing the GHG & Energy Target Management System in 2010 and as one subject to the emissions trading system, which was implemented in 2015. We dutifully observe the regulations of the the emissions trading system and strive to reduce GHG through the development of methods of reducing energy use, accumulation of relevant knowhow, and investment in highly efficient facilities. Especially, we manage the energy use amount and GHG emission on a daily basis through the Operation Information System (OIS), etc. Through such measures, we check whether we can attain the annual GHG reduction objective in advance as part of the effort to cope with the need more efficiently.

JOINING RE (RENEWABLE ENERGY) 100 AND EXPANDING THE USE OF RENEWABLE ENERGY

SKC, jointly with other affiliates of the SK Group, became the country’s first company to joint RE100 in Dec. 2020. We plan to have renewable energy meet our power requirements fully by 2050.

* https://www.there100.org/re100-members?ref=re-source&page=22

* https://www.there100.org/re100-members?ref=re-source&page=22

COMMERCIALIZATION OF ECO-FRIENDLY HPPO, THE FIRST ATTEMPT OF ITS KIND IN WORLD

In 2008, we at SKC succeeded in the commercialization of HPPO production of eco-friendly propylene oxide (PO), the first of such attempt made in the world. HPPO is an eco-friendly method of making PO through the reaction of propylene (C3=) and peroxide (H2O2). The process does not produce any toxic substance apart from water.

ADOPTION OF WASTE HEAT COLLECTION SYSTEM

SKC has come up with a method of turning hot water produced in the manufacturing process into a heat source. As a result, we came to reduce energy use by more than 60% compared to the original design. We have acquired the patent right* for the energy-saving technology both at home and abroad.

* Patent right for waste heat recovery system: applied in Korea, US, Japan, China, Europe, and Germany

* Patent right for waste heat recovery system: applied in Korea, US, Japan, China, Europe, and Germany

Green Company

SKC keeps upgrading the SHE management to make employees and related parties happier and become a model enterprise for a local community. As a result, we earned diverse certifications such as ISO14001 and Safety & Health Management System (ISO 45001) and Green Company from government and independent agencies.

ZWTL certification & recycling of more wastes

SKC vows to recycle increasingly more wastes each year to upgrade ZWTL certification*, endeavoring to have all worksites ZWTL-certified by ‘25.

※ SKC ZWTL certification status

* ZWTL (Zero Waste To Landfill) : certification of 80% or higher recycling ratio (Silver, Gold, and Platinum certificates to be granted at or over 90% and upgraded every year)

※ SKC ZWTL certification status

| ‘21 | ‘22 | |

|---|---|---|

| Worksite (grade) | SK nexilis Jeongeup (Gold) | SK nexilis Jeongeup (Gold) SK picglobal, Ulsan (Gold) |

SHE Golden Rules (SGR)

We have established and operated SHE Golden Rules to root safety-first culture and prevent accidents and disasters.

For this, we have discovered and prevented hazardous factors on the manufacturing sites and summarized and distributed the matters that must be confirmed and observed. We have continuously posted the Rules in major spots and advertised them through the related campaigns and others. In addition, they have been actively introduced to recruits and employees of new partners.

For this, we have discovered and prevented hazardous factors on the manufacturing sites and summarized and distributed the matters that must be confirmed and observed. We have continuously posted the Rules in major spots and advertised them through the related campaigns and others. In addition, they have been actively introduced to recruits and employees of new partners.

SGR (Suwon Plant)

-

1. For the operations which require the issuance of safety work permit, perform risk assessment before operation and remove hazardous elements.

2. Observe the safety rules on the rotating body operations such as roll cleaning.

3. Take safety actions on the operations having a possibility of serious accidents (e.g., suffocation in a closed space, fall from a high construction site, etc.).

4. During the repair of process and electrical facilities, isolate or separate the energy sources and hazardous substances and properly lockout and tagout them.

5. All works are executed after getting final approval on the safety work permit.

6. Understand the designated protective equipment by process and make sure that you put it on in the required zone. The supervisor shall monitor and supervise if this instruction is properly observed. -

1. For the operations which require the issuance of safety work permit, perform risk assessment before operation and remove hazardous elements.

2. Take safety actions on the operations having a possibility of serious accidents (e.g., suffocation in a closed space, fall from a high construction site, etc.).

3. During the repair of process and electrical facilities, isolate or separate the energy sources and hazardous substances and properly lockout and tagout them. attach ‘Lock Out’ and ‘Tag Out’ stickers.

4. All works are executed after getting final approval on the safety work permit.

5. . Understand the designated protective equipment by process and make sure that you put it on in the required zone. The supervisor shall monitor and supervise if this instruction is properly observed.

6. Operate and park an internal vehicle within the designated place only. Make sure that you observe safety speed limits, fasten the seat belt and put on protective equipment (forklift). -

1. For the operations which require the issuance of safety work permit, perform risk assessment before operation and remove hazardous elements.

2. All works are executed after getting final approval on the safety work permit.

3. Understand the designated protective equipment by process and make sure that you put it on in the required zone. The supervisor shall monitor and supervise if this instruction is properly observed.

4. Operate and park an internal vehicle within the designated place only. Make sure that you observe safety speed limits, fasten the seat belt and put on protective equipment (forklift).

5. Smoking is prohibited in the manufacturing plant. Workers should smoke in a designated area only. -

1. For the operations which require the issuance of safety work permit, perform risk assessment before operation and remove hazardous elements.

2. Take safety actions on the operations having a possibility of serious accidents (e.g., suffocation in a closed space, fall from a high construction site, etc.).

3. During the repair of process and electrical facilities, isolate or separate the energy sources and hazardous substances and properly lockout and tagout them.

4. All works are executed after getting final approval on the safety work permit.

5. Understand the designated protective equipment by process and make sure that you put it on in the required zone. The supervisor shall monitor and supervise if this instruction is properly observed.

SGR (Jincheon Plant)

-

Safety Operation Permit

- Start operation after the safety work permit is issued.

- Risk assessment and education prior to operation

-

Emergency Training

- Preparation of emergency response scenarios & regular training

- Emergency situation reporting, analysis of causes and development of countermeasures

-

Access to the Closed Space

- Measure hazardous gas and oxygen levels prior to operation.

- Prepare emergency action plan and rescue equipment.

-

Personal Protective Equipment

- Put on and use appropriate personal protective equipment.

- Keep personal protective equipment clean and sanitary.

-

Change Control

- Observe the change control procedures.

- Change-related education and check prior to operation

-

Traffic Safety

- Observe the safety speed limits (20km/h) in the business site.

- Observe the safety speed limits for a forklift (8km/h).

-

Heavy Object Handling

- Observe the heavy object handling plan.

- Comply with rated load during hoist and crane operations.

-

Accident Reporting

- Report all accidents which occur during operation according to the related procedures.

-

Arrangement

- Keep the workplace tidy and clean.

- Keep things clean and tidy as a habit after operation.

-

Lock Out Tag Out (LOTO)

- Observe the LOTO procedures during facility maintenance/cleaning.

- Prohibition on interlock bypass or random unlocking

SGR (Ulsan Plant)

- SHE Golden Rules

-

- 1. Execute all works after getting final approval on the safety work permit.

- 2. All workers should complete a safety training program before operation.

- 3. Put on designated protective equipment when handling hazardous materials.

- 4. Make sure you take a fall prevention action before operation at a high area.

- 5. Measure hazardous gas and oxygen levels regularly during operation in a closed space.

- 6. When a vehicle (2.5t or higher) is parked or stopped, secure it with a wheel chock.

- 7. When there are changes, review them and check prior to operation.

- 8. Smoking is prohibited in the manufacturing plant. Workers should smoke in a designated area only.

- 9. All vehicles should observe internal speed limits and be parked in the designated area only.

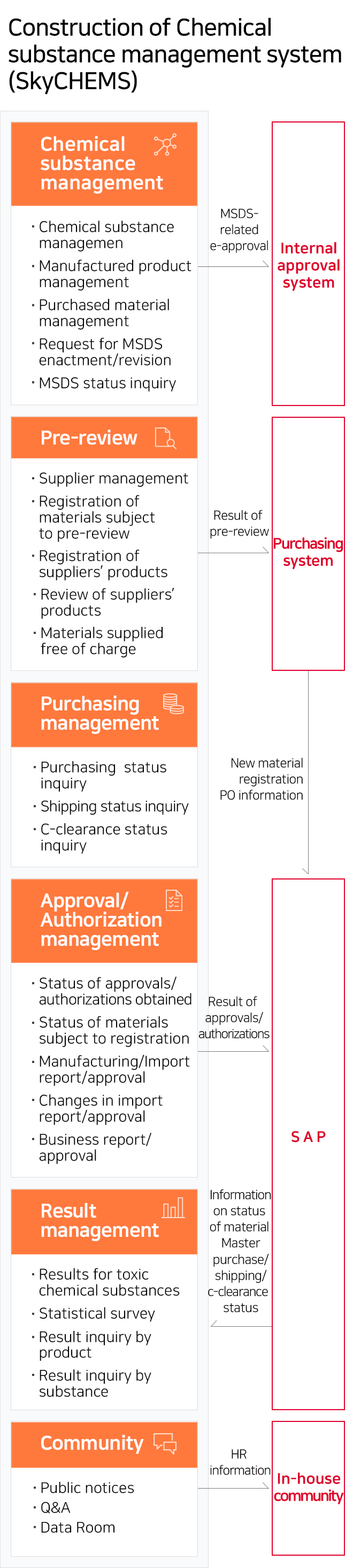

SkyCHEMS

SKC observes Chemicals Control Act reinforced in 2015 and Chemical Registration & Assessment Act. In the Republic of Korea, for example, we have established a chemical management system called ‘SkyCHEMS’ and managed all chemicals we manufacture, purchase, store and distribute. In addition, we have developed and implemented our own chemical management regulations, procedures and standards.

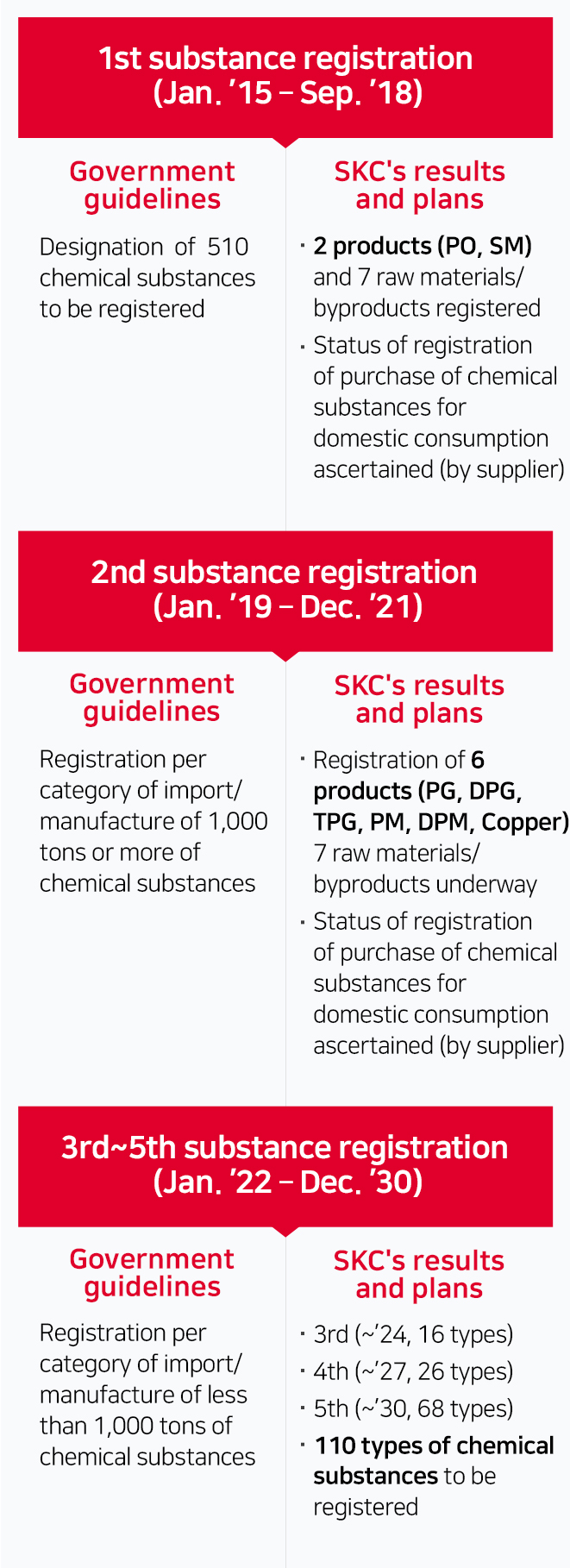

How to cope with regulation at home and abroad (Act on the Registration, Evaluation Etc. of Chemicals / Chemical Substances Control Act, abroad)

- All chemical substances used at SKC’s places of business are registered in advance as per the government’s guidelines.

- We operate a transparent, safe process for using chemicals according to our chemical management system (SkyCHEMS).

* New chemical substances

- - One major chemical substance of transparent PI products registered

- Status of coping with the regulation of chemical substances abroad

| Country | Status of coping |

|---|---|

| EU REACH | Four major products (PO, PG, DPG, and TPG) registered |

| Turkey KKDIK | Six major products (PO, PG, DPG, TPG, PM, DPM) pre-reported* |

| Vietnam | One major product (HR-44S) registered previously |

| Others | Need to monitor/check the status of registration concerning the regulation of chemical substances by country |

* Pre-report: Report on the amount of distribution for the provision of grace period for registration of chemical substances

(Immediate registration is required if grace period is not provided.)

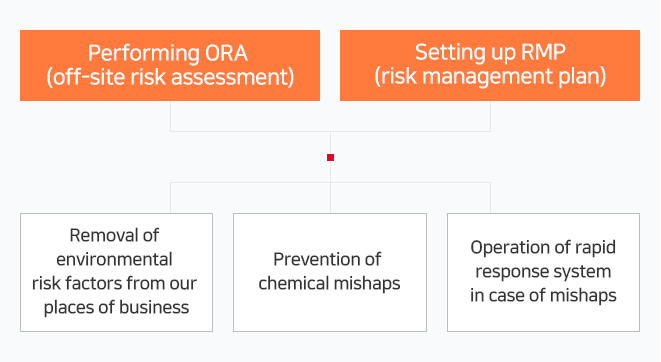

- Complying with the Chemical Substances Control Act

We have continued to consult expert institutions and invest in facilities for the safe management of chemicals in compliance with said Act, which was amended in 2015.

- Improvement in hardware: Striving to invest in and improve facilities designed to prevent chemical mishaps like improvement in indoor storage of chemicals and installation of trench in places where chemicals are handled

- Improvement in software: Striving to engage in environmental improvement activities including composition of a system for using substances replacing toxic ones

Putting an end to the use of toxic chemicals

SKC strives to turn itself into an eco-friendly workplace.

1. We continue to strive to replace toxic chemicals with eco-friendly substances in all sectors of our production process and product development.

2. In product development, we prioritize eco-friendly materials. We engage in the eco-friendly business sector by using PLA films instead of plastics and developing silicon products containing no water-polluting substances.

1. We continue to strive to replace toxic chemicals with eco-friendly substances in all sectors of our production process and product development.

2. In product development, we prioritize eco-friendly materials. We engage in the eco-friendly business sector by using PLA films instead of plastics and developing silicon products containing no water-polluting substances.

| By | Actions taken | Expected effects |

|---|---|---|

| 2012 | Development and application of PROS Free Coating Formulation | Coping with regulations on toxic chemicals at home and broad |

| 2013 | Development and application of Dioxane-Free Coating Formulation | Coping with regulations on water-polluting substances at home and broad |

| 2019 | Replacing the toxic substance (NaOH) used to neutralize wastewater with ordinary chemicals | Reduction of risks in handling/managing toxic substances |

| 2019 | Introduction and commercialization of Co-PET that will replace the PVC goods used in furniture and buildings | Coping with customers’ request for PVC-free products |

| Developing (2021(Goal)) | Development of silicon products with zero water-polluting chemicals | Coping proactively with regulations on water-polluting chemicals at home and broad |

Hazardous chemical emission

[Unit : ton]

| Category | 2021 | 2022 | 2023 | Notes |

|---|---|---|---|---|

| SKC | - | - | - | Not subject |

| SK picglobal | 13.20 | 9.44 | 1.72 | |

| SK nexilis | - | - | - | Minor emission business sites excluded |

| SK enpulse | 0.05 | - | - | Minor emission business sites excluded |

| Pucore | 0.24 | 0.26 | - | Excluded since 2023 (Divested) |

| Total | 13.49 | 9.70 | 1.72 |