NEWS

l KCFT boasts world-class technological prowess and productivity in copper foil production, expects to increase its production capability three-fold by 2022.

l SKC is committed to assisting KCFT’s continuous growth.

SKC (President Lee Wan-jae, www.skc.kr) is set to take over KCF Technology (KCFT), a world-class manufacturer of copper foil, a core material of EV batteries, thereby equipping itself with an engine of future growth in the mobility business sector.

On the morning of June 13, the Company’s Board of Directors (BOD) decided to take over all equities of KCFT for 1.2 trillion won and signed a Share Purchase Agreement (SPA) with Kohlberg Kravis Roberts (KKR), a global investment firm. The Company plans to finish the entire takeover procedure, including the detailed due diligence and approvals/authorizations, by the earliest possible date, at which point KCFT will start over as one of SKC’s subsidiaries.

Copper foil, a core material used in secondary battery cathodes, is manufactured using a highly sophisticated production process. The thinner the battery copper foil, the more active cathode materials can be contained by a battery. As such, the production of thin copper foil is the first step to making high-capacity, lightweight batteries.

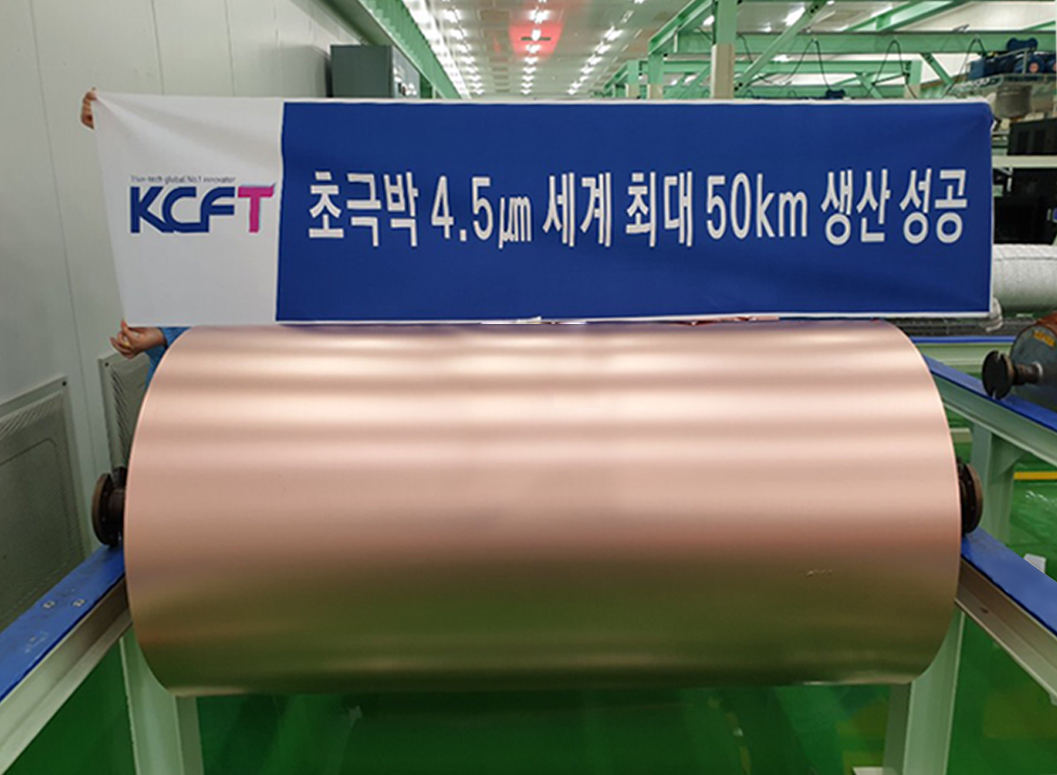

KCFT boasts the world’s best technological prowess in the production of secondary battery copper foil, which it supplies to battery manufacturers all over the world. Just last month it displayed its sheer technological prowess by successfully mass producing a 50-kilometer-long roll of ultra-thin (4.5㎛ thick, which is about one-thirtieth the diameter of a strand of human hair) copper foil, the longest such roll ever produced in the world. KCFT is now streets ahead of rivals in the production of ultra-thin, high-strength foil and boasts the world’s best productivity in the field.

The copper foil market is expanding rapidly amid the increase in the demand for EV batteries. As such, SKC plans to enhance its production capacity in copper foil three-fold by 2022, and aims to supply the rapidly growing world market _ base_d on its existing trust-_ base_d relationships with major battery manufacturers both in and out of the country. It also plans to grow with customer businesses by supplying thinner and better copper foil, utilizing the film production know-how it has accumulated over the last forty years.

The Company will also listen to the opinions of KCFT employees in the due diligence process so that it can continue to grow as a subsidiary of SKC, which is known for pursuing growth _ base_d on its employees’ happiness.

With the aforementioned takeover, SKC has secured a core engine for future growth in the mobility business sector. It has striven to improve its mode of operation under the motto of “MARKET INSIGHT”, which it announced in 2016, and its new vision as a Global Specialty MARKETER, which stresses the importance of combining existing technologies creatively. Notably, the Company has focused on establishing a business portfolio centered on the mobility, semi-conductor and environmentally-friendly business sectors since 2017.

On the occasion, SKC President Lee Wan-jae said, “We will do everything we can to bring happiness to all our employees through the continuous growth of both SKC and KCFT. We will also strive to enhance the Company’s corporate value and strengthen the country’s overall competitiveness in the material industries, availing ourselves of this takeover as an opportunity for ‘Deep Change’.”

[Attachment

1: A view of a KCFT factory in Jeongeup, Jeonbuk]

[Attachment 2: The 50-kilometer-long roll of ultra-thin (4.5㎛ thick, or approximately one-thirtieth the diameter of a strand of human hair) copper foil, the longest roll of its kind in the world, which KCFT successfully mass produced last May.